- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

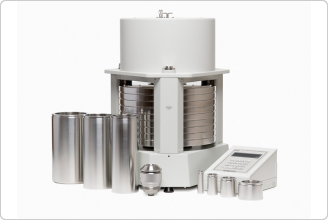

PG7000-AMH - Automated Mass Handler for PG7000 Piston Gauges

Automated Mass Handler

for PG7000 Piston Gauges

PG7000™, already the world's most advanced piston gauge, takes another step ahead with the introduction of AMH™ automated mass handling technology. Finally, tedious, error prone and wear inducing manual mass manipulation can be eliminated from high end piston gauge operation… over the full pressure range, in a bench top system, at a reasonable cost.

The AMH system is an optional accessory to PG7000 platforms. It can be added to existing platforms or ordered with new installations. Two models are available to cover the complete PG7000 line of gas and oil operated piston gauges… including absolute mode with a vacuum reference. Thanks to the PG7000's unique system architecture, the exact level of automation appropriate for the application can be configured with standard components. Automate mass handling while maintaining direct operator control over pressure generation and adjustment, or use standard pressure controllers to automate pressure control and make fully automated piston gauge operation a reality. In all cases, PG7000’s unified approach assures a simple, integrated system with a single local and remote interface.

AMH technology

To install the AMH masses, a binary mass loading tray isplaced on the piston cap and a mass bell is installed over the tray. The mass set's main mass discs are hung from the mass bell. Tubular binary masses are placed in descending sequence on the mass bell hanger and on the tray.

The mass handling system is placed over the installed mass set and controlled by the PG7000 platform, using RS232 communications from the platform's COM3 port.

To load a specific mass value, the mass handling system raises the entire mass load above the piston upper end of stroke to the mass selection position. The mass is raised by a pneumatically actuated lifter acting on a lifter shaft connected to the binary mass spindle. Each tubular binary mass that is not to be loaded is held in place by engaging three selector pins. The three main mass columns are rotated synchronously so that the main masses not to be loaded are held in place by the columns' retention ledges and masses to be loaded face release flats. When the mass selection is complete, the lifter moves down, placing the lifter shaft, binary spindle, bell and all the released masses onto the piston.

The AMH mass handling system is designed and tested to provide years of reliable, maintenance free mass manipulation.

Mass loading control

Control of the mass handling system is integrated into PG7000’s intelligent operation. In pressure entry mode, when a target pressure command is entered from the front panel or remotely, PG7000 calculates the mass required to achieve the target pressure. It then stops piston rotation and loads the mass value by sending a command to the AMH. The true value of mass loaded and exact pressure value achieved are reported and updated real time. In mass entry mode, the requested value is loaded directly.

The mass actually loaded by the AMH is as close as possible to the target value within AMH's 100 g loading resolution. If more precise mass loading is specified, the operator is instructed to load trim masses on the trim mass tray (not available in absolute mode with vacuum reference).

Access to piston-cylinder module

The same piston-cylinder modules used in PG7000 with manual mass handling are used with AMH. The piston-cylinder module can be removed and reinstalled in less than 5 minutes, and requires about the same amount of effort as a single, manual mass handling calibration sequence.

The piston-cylinder module is accessed by removing the AMH mass handling system and masses. The procedure is to load all of the mass on the piston so that no masses are in contact with the mass handler. The mass handler is lifted off of the PG7000 platform vertically, leaving behind the complete loaded mass set. The masses are then removed manually to access the piston-cylinder module.

AMH-38, 38 kg under vacuum for PG7601

The AMH-38 provides automated mass handling of a 38 kg mass set for the PG7601 piston gauge platform. The mass handling system is integrated into a vacuum chamber which provides KF40 vacuum fittings for connection of a turbo molecular vacuum pump and external vacuum gauge if desired. Automated mass handling eliminates the need to break the vacuum between pressure points and reference vacuum as low as 0.01 Pa (< 0.1 mTorr) can be maintained indefinitely.

AMH-100, 100 kg for PG7102, 7202, 7302

The AMH-100 provides automated mass handling of a 100 kg mass set for the PG7102, PG7202 and PG7302 piston gauge platforms.

The 100 kg mass set results in a very wide range on a single piston-cylinder module, minimizing the need for piston-cylinder changes. A mass set of less than 100 kg can be configured if less than 100 kg is needed.

Specifications

AMH-38 Piston-Cylinder Ranges and Automated Increment |

||||||

| Piston-cylinder module | Minimum pressure | Maximum pressure with maximum 38 kg mass load |

Minimum automated increment | |||

| kPa | Psi | kPa | Psi | kPa | Psi | |

| PC-7100/7600-10-L | 7 | 1 | 380 | 55 | 1 | 0.15 |

| PC-7100/7600-10, TC | 10 | 1.5 | 380 | 55 | 1 | 0.15 |

| PC-7100/7600-20 | 18 | 2.6 | 760 | 110 | 2 | 0.3 |

| PC-7100/7600-50 | 35 | 5 | 1900 | 275 | 5 | 0.7 |

| PC-7100/7600-100 | 70 | 10 | 3800 | 551 | 10 | 1.5 |

| PC-7100/7600-200 | 140 | 20 | 7600 | 1100 | 20 | 3 |

AMH-100 Piston-Cylinder Ranges and Automated Increment |

||||||

| Piston-cylinder module | Minimum pressure | Maximum pressure with maximum 100 kg mass load |

Minimum automated increment | |||

| kPa | Psi | MPa | Psi | kPa | Psi | |

| PC-7100/7600-10-L | 10 | 0.5 | 1 | 150 | 1 | 0.15 |

| PC-7100/7600-10, TC | 13 | 1.9 | 1 | 150 | 1 | 0.15 |

| PC-7100/7600-50 | 50 | 7 | 5 | 750 | 5 | 0.7 |

| PC-7100/7600-100 | 100 | 14.5 | 10 | 1500 | 10 | 1.5 |

| PC-7100/7600-200 | 200 | 29 | 111 | 16001 | 20 | 3 |

| PC-7200 or 7300-100 | 100 | 14.5 | 10 | 1500 | 10 | 1.5 |

| PC-7200 or 7300-200 | 200 | 29 | 20 | 3000 | 20 | 3 |

| PC-7200 or 7300-500 | 500 | 72.5 | 50 | 7500 | 50 | 7.3 |

| PC-7200 or 7300-1 | 1000 | 145 | 100 | 15000 | 100 | 14.5 |

| PC-7200 or 7300-2 | 2000 | 290 | 2002 | 300002 | 200 | 29 |

| PC-7300-5 | 5000 | 725 | 500 | 72500 | 500 | 75 |

1 Limited by fall rate.

2 100 MPa (15 000 psi) max in PG7202.

Automated Mass Handler |

|

| Electrical Power |

100 to 240 VAC, 50 to 60 Hz 30 W max consumption |

| Normal Operating Temperature Range |

15 to 35 °C |

| Weight (Mass Handler Only) |

AMH-38: 18 kg (40 lb) AMH-100: 12 kg (26 lb) |

| Dimensions |

AMH-38: 41 cm H x 37 cm W x 38 cm D (16.3 in. x 14.6 in. x 15 in.) AMH-100: 41 cm H x 41 cm W x 36 cm D (16.3 in. x 16.1 in. x 14.1 in.) |

| Communications Port | RS-232 (COM1), controlled by PG7000 platform |

| Drive Air Supply | 550 kPa (80 psi) "shop air" |

| Drive Air Connection |

Quick connect equivalent to Swagelok⪚ QM Series (QM2-B200) |

| AMH-38 Vacuum Chamber |

Fittings: (2) KF40 for pump and vacuum gauge upgrade Typical Residual Vacuum: < 10 mPa (0.08 mTorr) with 70 l/s turbo pump Higher pressure with other pumps |

| Mass Changing Time | < 15 sec |

| CE Conformance | Available, must be specified |

Mass Set: MS-AMH-38, 25, 13 |

|

| Fits PG7000 Platforms | 7601, 7607 |

| Minimum mass (piston and bell) | 0.7 kg (1 kg w/ tungsten carbide 10 kPa/kg) |

| Maximum mass load | 38 kg, 25 kg or 13 kg |

| Minimum automated increment |

100 g (373 increments), trim masses to 0.01 g may be loaded manually |

| Mass set composition |

Piston 0.2 kg (10 kPa/kg t-c 0.5 kg) Bell, tray, lifter assembly 0.5 kg (6) cylindrical binary masses of 0.1, 0.2, 0.4, 0.8, 1.6, 3.2 kg (5, 3 or 1) main mass disks of 6.2 kg each (1) trim mass set of 50 g to 0.01 g* |

| Mass uncertainty | ± 5 ppm or 1 mg |

* Trim masses loaded manually onto trim mass tray when needed.

Mass Set: MS-AMH-100, 80, 60, 40 |

|

| Fits PG7000 Platforms | 7102, 7202, 7302, 7307 |

| Minimum mass (piston and bell) | 1 kg |

| Maximum mass load | 103.7 kg, 87.3 kg, 63.7 kg or 43.7 kg |

| Minimum automated increment |

100 g (1 027 increments), trim masses to 0.01 g may be loaded manually |

| Mass set composition |

Piston 0.2 kg (10 kPa/kg t-c 0.5 kg) Bell, tray, lifter assembly 0.8 kg (7) cylindrical binary masses of 0.1, 0.2, 0.4, 0.8, 1.6, 3.2, 6.4 kg (9, 7, 5 or 3) main mass disks of 10 kg each (1) trim mass set of 50 g to 0.01 g* |

| Mass uncertainty | ± 5 ppm or 1 mg |

* Trim masses loaded manually onto trim mass tray when needed.

| Model Name | Description |

|---|---|

| AMH-38-VAC |

Automated mass handler, 38 kg maximum |

| MS-AMH-13 |

13 kg mass set, AMH |

| MS-AMH-25 |

25 kg mass set, AMH |

| MS-AMH-38 |

38 kg mass set, AMH |

| AMH-100 |

Automated mass handler, 100 kg maximum |

| MS-AMH-40 |

40 kg mass set, AMH |

| MS-AMH-60 |

60 kg mass set, AMH |

| MS-AMH-80 |

80 kg mass set AMH |

| MS-AMH-100 |

100 kg mass set, AMH |

| AMH-100-VAC-CE |

CE compliant |

| AMH-38-VAC-CE |

CE compliant |

| Product Manuals |

|---|

| Data Sheets |

|---|

| Instruction Sheets |

|---|

| Video |

|---|

| PG7202 High-Pressure Automated Pneumatic Piston Gauge System Demo Video |

| On-Demand Webinars |

|---|

| Pressure Series, Part 3 of 3, Advanced Pressure Calibration |

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- About Us

Sidebar Request a Quote

Request a quote