- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

Temperature baths increase stability in medical device manufacturing and tempering process

Fluke salt baths help ensure consistent and repeatable processes for medical device manufacturing and Nitinol forming by providing stability and uniformity specifications that are up to 10x that of a typical heat-treating bath.

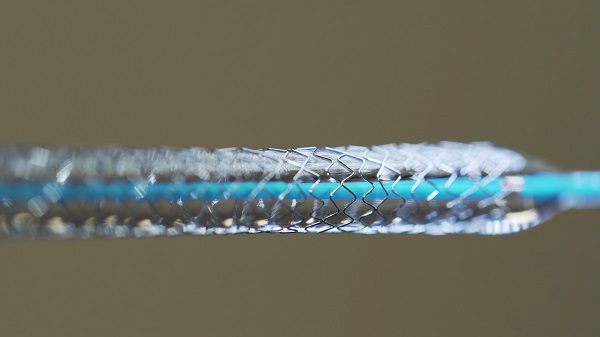

Precise heating and quenching are critical to molding metal medical devices. These nitinol devices must be able to compress down to a fraction of their end size and return to the designed shape and size without any fear of breakage or disforming from their initial cast design. For example, when used for stents or blood clot filters, these devices are folded into a catheter, where they are then guided through the body, following the twists and natural paths without damage to the individual or the implant. Once in place the patient’s body natural temperature causes the device to return to its original cast shape/size as it was formed to in the heat-treating process.

Metals like nitinol, a nickel titanium alloy, are widely used for these medical applications. The metal alloy exhibits both thermal shape memory behavior and super-elasticity. A wire or mesh can be set into a form using a tempering process so they will remember that form even after being compressed.

Nitinol tempering process

In order to prepare nitinol devices for medical use, the devices must be tempered, or heat treated. This general medical device quenching and tempering process involves heating the nitinol wire to incredibly high temperatures, then cooling it to create the shape memory. Each company that does medical device manufacturing has tailored the process a little bit differently; for example, heating to different temperatures, or cooling the wire at different speeds.

However, the one thing all companies are striving for is consistency and repeatability in the process. Resulting in as little deviation possible from one device to the next during manufacturing. Having a developed process that is not only repeatable with consistent results, but which also creates uniform, high-quality pieces is paramount in the medical device manufacturing industry.

Use a salt calibration bath for better stability and uniformity

We found our way into this industry when a medical device manufacturer was looking to improve consistency of their heat-treating process. They were struggling with the wide temperature swings being observed in the current process using sand calibration baths and were also looking to improve throughput in the process. After a few discussions we were able to find a solution to both with the Fluke 6050H Extremely High Temperature Calibration Salt Bath.

The Fluke 6050H salt bath, being initially designed for calibration, provided up to 10 times better stability and uniformity specs over the typical heat-treating baths in use. This spec, coupled with the fluid mass (125 pound of molten salt) and optional 1000W axillary heater, allowed for not only more consistency, but also a quicker throughput due to the ability to quench, recover, and temper from the room temperature form and wire. This provided more stable, repeatable, and quicker results in the device manufacturing process.

Wire forming with calibration baths

Adding the salt bath to their workflow, to heat and quench the devices within the bath, this company has seen an increase in the quality control of their nitinol wire devices. Calibration baths are designed to be incredibly precise and stable, offering a medical device manufacturing firm more control over the details of the tempering process. A Fluke Calibration bath offers temperature precision, stability and uniformity, and versatility.

Temperature precision

A Fluke temperature calibration salt bath can be set to an exact temperature with +/-1.0C over the range of 180-550 °C, creating a highly controllable and repeatable process for medical device manufacturing. Being able to set the temperature for the heating portion, as well induce 1000 Watts of boost heating during the initial quench of the wire forming process, helps create a repeatable and consistent process, netting a better-quality product, and possibly lowering risk based on a manufacturing deviation.

Stability and uniformity

At the max temperature of 550 °C, a salt temperature bath will hold a stable temperature within ±0.008 °C and hold uniform (top to bottom/side to side) temperature within ±0.002 °C. This level of certainty creates a best-case environment for heat-treating devices which, in turn, lead to a better-quality product.

Versatility

While the salt calibration bath has been used by one customer, Fluke offers a variety of calibration bath types and fluids, from compact, deep-well, hot, cold, resistor, and custom bath types, as well as fluids covering temperature ranges from –100 °C to 550 °C. Please reach out to us at calibrationdevelopment@flukecal.com to discuss this or any other unique temperature application.

Keep learning

- How to Select the Right Temperature Calibration Bath webinar

- How to Choose a Calibration Bath app note

- Fluke Calibration Bath Safety Features app note

See related products

- Fluke Calibration temperature baths

- 6050H Extremely High Temperature Calibration Salt Bath

- Calibration bath selection guide

Get help

- Customer and technical support

- Speak with a calibration product expert about your equipment needs

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- About Us

Sidebar Request a Quote

Request a quote