- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

Druckkalibrierung

Messtechniker, MSR-Techniker und Elektrotechniker benötigen zuverlässige, genaue und robuste Geräte. Wir haben sie. Ob Ihre Geräte für den Außeneinsatz, in einem Kalibrierlabor oder für beides benötigt werden: In den folgenden Kategorien finden Sie einen vollständigen Satz für elektrische/Signal-, Druck- und Temperaturanwendungen.

Was ist Druckkalibrierung?

Pressure calibration is the comparison of the output of a device used to measure pressure with the output of another pressure measuring device or a pressure measuring standard. For pressure calibration, the DUT generally has to be connected to the standard device by cables. Then pressure must be generated in the measuring circuit. The outputs of the devices are compared for one or more pressures, usually from the lowest reading to the highest reading of the measuring range of the device under test or the range for which it is commonly used. This comparison is made in a chain from the highest primary pressure realization down to everyday pressure gauges to ensure that the pressure measurements are correct and conform to recognized or mandated standards.

Where is pressure calibration used?

National metrological institutes

A national metrological institute (NMI) is a facility that is responsible for the implementation and dissemination of measured values according to the International System of Units (SI). Usually there is an official NMI in every country, whose task it is in some countries to enforce the metrological standards in industry and science. Fluke Calibration's piston gauges can be found in NMI laboratories around the world. They are used primarily to determine and disseminate pressure values with low uncertainties. The PG9000 piston pressure gauges from Fluke Calibration are specially designed for the requirements of metrological institutes that realize and disseminate pressure values with direct traceability to dimensional measurements.

Primary calibration laboratories

Primary calibration laboratories are the link between national metrological institutes or primarily derived measurements and secondary laboratories and working standards. These laboratories, which include the best calibration facilities from the military, research and business sectors, perform high-precision calibrations in small numbers. A primary pressure calibration laboratory usually works with primary pressure standards , e.g. B. the pressure gauges PG7000 or 2400, with traceability to a national metrological institute or another primary calibration laboratory. To disseminate primary pressure values for work standards, these laboratories can also use high-performance transmission standards such as pressure controllers / calibrators and reference pressure monitors(PPC / RPM and 7000) or Pressurements use pressure compensators .

Secondary laboratories and equipment calibration workshops

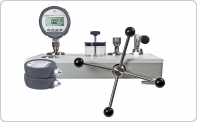

Most of the institutions that perform pressure calibrations around the world use transmission or work standards to support pressure measuring devices (manometers, transmitters, transducers, etc.) as well as other work calibration standards. These laboratories can perform a range of tests from basic to high-precision calibrations, usually in greater numbers than an NMI or a primary calibration laboratory. The traceability of pressure standards is maintained by a primary laboratory or another secondary calibration laboratory. To support working standards and high-performance measuring devices, a secondary pressure laboratory uses high-performance transmission standards such as pressure controllers / calibrators and reference pressure monitors(PPC / RPM and 7000) or pressurements pressure compensators . The PG7000 or 2400 piston pressure gauges can be used for more demanding applications. The same high-performance transmission standards or work standards can be used for the everyday calibration of measuring devices and work standards with lower power, e.g. B. the electronic pressure compensator E-DWT or the pressure controller / calibrator PPC4E .

On-site, stationary and mobile calibration

Often the device to be calibrated cannot be removed from its process. Or if the calibration standard is brought to the device, this not only reduces downtime, but also saves considerable resources. Fluke Calibration offers portable solutions for on-site calibration, e.g. B. Pressurements pressure compensators and pressure comparators , Fluke Calibration reference pressure monitors RPM4 and the electronic pressure compensator E-DWT . We can also offer a mobile solution (calibration trolley, transport case or rack installation system) with our individual calibration systemsprovide. For applications where a portable handheld solution is required, Fluke Calibration has a line of industrial process calibration equipment , including rugged pressure calibrators and modules.

Manufacture and maintenance of pressure sensors

Die Hersteller von Manometern, Drucktransmittern, Druckmessumformern, Druckschaltern, Druckanzeigen und anderen Druckmessgeräten verwenden Kalibriernormale, um sicherzustellen, dass ihre Produkte der Spezifikation entsprechen. Unter Umständen bieten sie auch rückführbare Druckkalibrierung mit neuen Geräten und Kalibrierdienstleistungen im Rahmen der Unterstützung nach dem Kauf an. Für diese Drucktest- und Kalibrierprozesse werden Druckreferenznormale benötigt, die je nach Leistung des zu testenden Produkts von grundlegenden Druckanzeigen bis hin zu Hochleistungskolbenmanometern reichen. Da Hersteller eine große Anzahl von identischen oder ähnlichen Druckgeräten testen und kalibrieren, verwenden sie häufig Druckcontroller wie die Druckcontroller/Kalibratoren PPC und 7000 von Fluke Calibration, um den Prozess zu automatisieren. Für Tests von hochpräzisen Druckgeräten werden die Kolbenmanometer PG7000 mit automatischen Massen-Auflagesystemen PG7000-AMH und PPC-Druckcontrollern automatisiert.

Flugdatenkalibrierung

In Flugzeugen werden zahlreiche Drucksensoren eingesetzt, die Treibstoffdruck, Kabinendruck, Motorleistung, Hydraulikdruck und andere wichtige Betriebsparameter ermitteln. Für den effizienten Betrieb und die Sicherheit des Flugzeugs muss die Kalibrierung dieser Sensoren genauestens eingehalten werden. Besonders wichtig ist das Pitot-Statik-System, das mithilfe eines Sensors für absoluten statischen Druck (Ps) Höhe und Steiggeschwindigkeit (Höhenmesser und Variometer) und mithilfe eines Sensors für absoluten Gesamtdruck (Pt) oder eines Sensors für Differenzstaudruck (Qc) die Fluggeschwindigkeit (Fahrtmesser) ermittelt. Die Flugdatencomputer moderner Avioniksysteme bestimmen anhand der Druckwerteingaben von diesen Sensoren kalibrierte Fluggeschwindigkeit (wahre Fluggeschwindigkeit), Mach-Zahl, Höhe und Höhentrend. Fluke Calibration bietet RVSM-konforme (für verringerten vertikalen Staffelungsabstand) Drucknormale für Pitot-Statik-Systemmessungen an. Der Flugdatenkalibrator 7750i und der Flugdatendruckmonitor RPM4-AD von Fluke Calibration werden zur direkten Kalibrierung von Flugdatensensoren sowie der Flugdaten-Testsets der Fluggesellschaft, die für deren Tests verwendet werden, eingesetzt. Diese Übertragungsnormale müssen die Rückführbarkeit auf primäre Drucknormale wie das Pitot-Statik-Kolbenmanometer 2468 und das Flugdatenkalibriersystem ADCS-601, aufrechterhalten, die für die Unterstützung von Flugdatengeräten optimiert wurden.

DH Instruments (DHI), Ruska Instruments, Pressurements, and the Fluke Calibration brand

Auswahl einer Lösung

Fluke Calibration has a wide range of pressure calibration solutions. Use the following links to quickly find all information about the available solutions. This guide is not intended to be an exhaustive study of your application; it is intended to guide you in the right direction. If you need help with a pressure calibration application or with your DHI, Ruska or Pressurements products, we are always at your side with professional advice. You can reach us by phone at 877-439-7225 or by email at sales@flukecal.com.

What is the accuracy / uncertainty of the device under test?

In which environment does the calibration have to take place?

Which pressure range and which test medium should be used for the device under test?

Are pressure generation and pressure regulation necessary?

To what extent can the calibration process be automated?

What else is needed for a complete pressure calibration solution?

Further reference material

The electronic pressure compensator - a modern replacement for the conventional pressure compensator

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- About Us

Sidebar Request a Quote

Request a quote