- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

Thermocouple Fundamentals: App Notes Series, 1 of 4

What is a thermocouple?

A thermocouple is a sensor used to measure temperature. Thermocouples are broadly used in many industrial and scientific applications due to their low cost, wide temperature ranges, high-temperature limits, and availability in many types and sizes. They are found in nearly all industrial markets including power generation, oil and gas, aerospace, semiconductors, pharmaceutical, biotechnology, food processing, and metals.

There are several hundred types of thermocouples constructed from different combinations of pure metals and alloys with their own unique characteristics and application suitability. Letter-types are given to the different thermocouple types to identify them. Type E, J, K, N, & T are “base metal” thermocouples, the most common types which use iron, constantan, nicrosil, copper, chromel and alumel materials. Type B, R, and S thermocouples are “noble metal” thermocouples (mainly platinum and rhodium materials), which are more expensive and used in high-temperature applications.

How does a thermocouple work?

In the 1820s, the Estonian-German physicist Thomas Johann Seebeck discovered that when a temperature difference between two dissimilar electrical conductors occurs, a corresponding voltage difference will be produced. This phenomenon is now known as the Seebeck or thermoelectric effect. The “Seebeck effect” is responsible for the behavior of thermocouples.

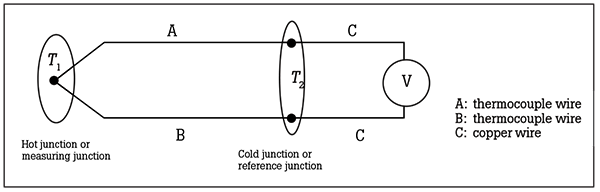

Figure 1 shows an example of thermocouple construction. A thermocouple consists of two dissimilar thermoelement wires A and B that are joined at one end T1 (the “hot” junction). The wires are insulated from each other along their lengths. The other end T2 (the “cold” junction) is maintained at a constant reference temperature (usually the melting point of ice). The cold junction is where the thermocouple wire transitions to copper wire for connection to a meter. Thermocouple wire can be connected directly to a meter or readout that is equipped with internal cold junction circuitry. This configuration is typically less accurate than when using an external cold junction maintained in a melting point of ice bath. The difference between the actual temperature T1 and reference temperature T2 is corrected electronically in the instrument measuring the thermocouple to indicate the actual temperature of T1 This adjustment is referred to as cold-junction compensation (CJC).

Figure 1. Thermocouple construction

Figure 1. Thermocouple construction

A voltage (thermoelectric force) is generated between the cold junction wires (T2) when the hot junction (T1) is exposed to a temperature that is different than the cold junction. An instrument connected to lead wires from the cold junction is used to read the thermocouple voltage.

Theoretically, this voltage measurement depends only on the temperature difference (T1 – T2). As T1 changes, the voltage output of the thermocouple changes proportionally to the change in temperature, but not linearly. The voltage output ranges from about -10 to 77 mV (depending on the thermocouple type and measurement temperature). The correlation of temperature versus voltage establishes a relationship that is unique to the various thermocouple types. These relationships are summarized in reference tables which provide the basis for thermocouple calibration.

Why do thermocouples need to be calibrated?

It is important to note that the thermocouple voltage is not generated at the “hot junction” where the two metals are joined (T1), but rather along the entire length (from T1 to T2) that the wires are exposed to in a temperature gradient. The temperature difference of the junctions and the measurement voltage is only correct if each wire of the thermocouple is homogeneous (uniform in composition). As a thermocouple is used in an industrial setting, the conductor wires can lose homogeneity through heat, chemical exposure, or mechanical damage (for example, a bend in the wire at a temperature gradient). If the inhomogeneous section of a thermocouple circuit is exposed to a temperature gradient, the measured voltage will differ, resulting in error. Therefore, thermocouples should be checked periodically and calibrated to ensure they are measuring correctly.

Base metal thermocouples (types E, J, K, N, and T) often develop “inhomogeneities” when used above 200 ºC. Heating these thermocouples in a furnace will further alter the wire, or moving them will change the temperature gradient. Both will lead to calibration errors. In these cases, “in situ” (on-site) calibration is required. This is done by inserting a reference thermometer alongside the thermocouple being calibrated and comparing the readings.

Noble metal thermocouples (types B, R, and S) can also suffer from inhomogeneities, but the effects are small (about 0.3 ºC) so they can be effectively calibrated. Base metal thermocouples used only at temperatures below 200 °C (Type K below 120 °C) generally do not exhibit large inhomogeneities and can be calibrated off-site.1

1Refer to the Measurement Standards Laboratory of New Zealand’s technical guide “Making Sense of Thermocouples” for more tips on thermocouple inhomogeneity.

See the other app notes in this thermocouple series:

2 of 4: How to Select Thermocouple Calibration Equipment

3 of 4: Calculating Uncertainties in a Thermocouple Calibration System

4 of 4: How to Calibrate a Thermocouple

Recommended Products:

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- About Us