- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

Buying the right temperature calibration bath for your laboratory

Liquid calibration baths are the most stable and uniform temperature sources for doing comparison calibration of temperature probes and sensors in a laboratory. They use a large fluid mass to maintain a stable and uniform test environment that provides the flexibility to calibrate probes and sensors of various sizes, shapes, and lengths.

Technician calibrating a temperature probe in a Fluke Calibration lab

Selecting the right calibra¬tion bath takes good research and analysis since many bath suppliers provide incomplete or confusing specifications. Some examples include:

- Performance may only be given for a single temperature point, not for the bath’s range

- Specifications don’t indicate which bath fluid was used in testing

- There’s no indication whether the specifications apply for the entire working volume

Since a calibration bath is a significant investment that will last many years, you’ll want to get the right information to make an informed decision. You must get comprehensive and clear specifications so that you can have the confidence your calibration bath will provide the performance you need for your application.

You will want to evaluate four key specifications when buying a calibration bath: temperature range, stability, uniformity, and tank size.

1 Temperature range

Bath suppliers normally publish and advertise a temperature range for each model. However, often no single bath fluid works well over the entire temperature range. For example, a Fluke Calibration 7341 Deep-Well Compact Bath has a range from -45 °C to 150 °C. Ethanol is a good fluid for this bath below 0 °C, but at temperatures above 0 °C another fluid such as silicone oil would be required. As a result, calibration labs must choose between changing bath fluids or using multiple baths to cover the full temperature range of their application.

At temperatures below 0 °C, Halocarbon, HFE, methanol, eth¬anol, ethylene glycol, Dynalene, and some silicone oil types are all candidate bath fluids. At temperatures above 0 °C, there are several silicone oil types available plus water and mineral oil that could be used. For extremely hot tem¬peratures above 300 °C, salt is a preferred option.

Viscosity is a measure of a fluid’s resistance to flow—we often think of it simply as “thickness.” It is commonly measured in “centistokes” (cSt). The higher the number of centistokes, the more viscous (or thick) a fluid is. Bath fluids which are too viscous create strain on stirring and pumping mechanisms and don’t adequately transfer heat uniformly from temperature sources to thermometers. We recommend using fluids whose viscosity is 50 centistokes or less at the desired control temperature. A homogeneous temperature within the “calibration zone” of a bath is required to achieve a calibration with low uncertainty. Low viscosity fluids reduce bath temperature gradients and contribute to better calibration uncertainties.

Please refer to the How to Select a Calibration Bath Fluid guide for more information on bath fluid selection.

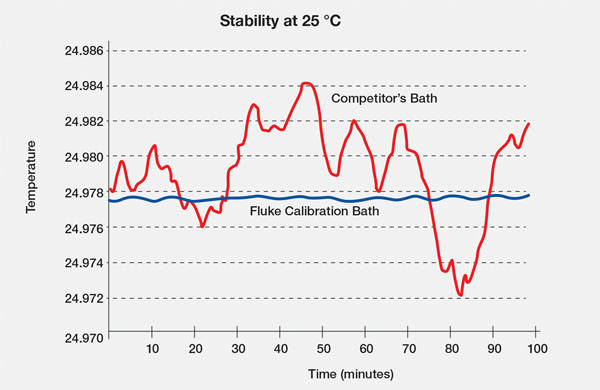

Fluke Calibration baths can achieve stability better than 1 mK for extended periods of time.

2 Stability

Stability is the ability of a bath to maintain a constant tempera¬ture over time. A bath’s stability will vary at different tempera¬tures. Many suppliers give you only one spec at or near ambi¬ent. Some give a single stability spec and don’t ever mention that it applies only to one tem¬perature or a narrow range. Ask about stability over the whole range that interests you.

Bath fluid also affects stability. The higher a fluid’s viscosity and the lower its heat capacity, the larger the effect on stabil¬ity will be. In addition to asking about the temperature range, ask what fluid was used when the specification was defined. For example, at 37 °C a bath will be more stable with water as the medium. If you’re going to use oil, expect somewhat larger instability. If your oil has high viscosity at 37 °C, expect even greater degradation in stability.

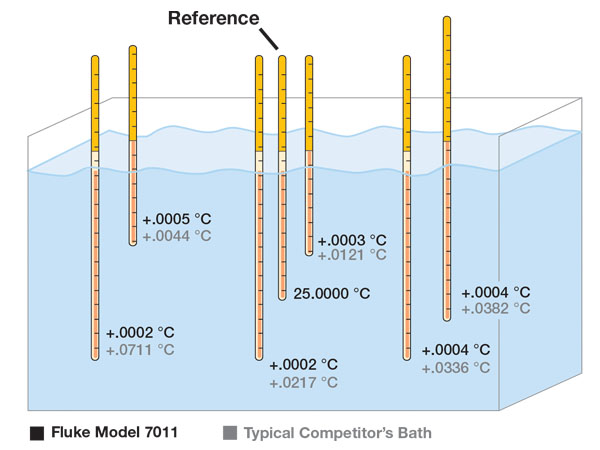

3 Uniformity

A bath can have good stability but poor uniformity. The bath must be homogenous in temper¬ature throughout the test zone where you’ll make your com¬parison measurements. When you place two or more probes in the fluid, they should be at the same temperature during your measurement. The uniformity spec defines the peak value for this error source. The more probes you’re testing, the larger the test zone and the more important uniformity becomes.

Uniformity depends mostly on the mixing of the bath fluid. Does the bath use a circulator pump for mixing? If it does, are there thermal flow patterns in the bath that interfere with uni¬formity? Be sure to check both vertical and horizontal tempera¬ture gradients.

A calibration bath may not have a horizontal temperature gradient, but still have a vertical gradient between different depths. This is a problem if your reference probe and the probes under test are not the same length. For example, you may be testing three-inch long probes and your reference is a 19-inch SPRT. You can only immerse the test probes to three inches, but if you immerse the SPRT to only three inches you don’t have sufficient depth to avoid stem effects that will cause measurement errors. If you properly immerse the SPRT and your bath suffers from vertical gradients, you won’t be measuring the temperature at the three-inch depth of your probes under test.

4 Tank size

The number of temperature probes and sensors to be cali¬brated should be considered. A bath with a larger tank size that allows large batches to be cali¬brated may be appropriate for laboratories that calibrate many probes and sensors each year. On the other hand, a bath with a smaller tank size would be a better fit for laboratories with a lower calibration volume.

When longer SPRTs, PRTs, and liquid-in-glass thermometers need to be calibrated, a bath with plenty of immersion depth should be evaluated. Tank opening size is an important factor when odd-shaped sensors (e.g. tri-clamp sanitary sensors) and sensors with large transmitter heads need calibration. When analyzing the tank size required for your application, be sure to allow for proper sensor immersion depth and fluid space below the sensors and between the sensors being tested and the tank wall.

Deviations from a central reference temperature taken in water with a 1/4-inch diameter PRT at 25 °C

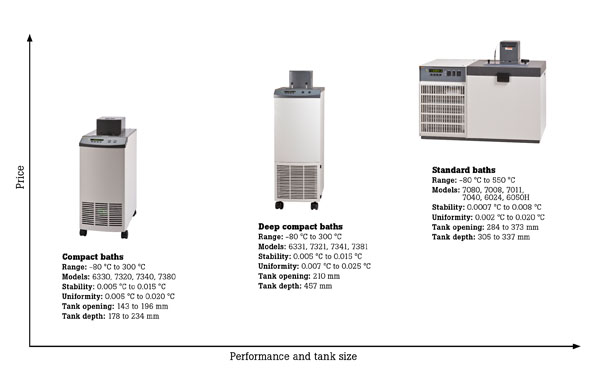

Fluke Calibration baths—A full product line to meet your needs

Fluke Calibration offers the broadest range of calibration baths in the industry. These baths include compact baths, deep compact baths, and full-size standard baths. Depending on the temperature range of your application, performance required, and your budget, we have a calibration bath to meet your needs.

Fluke Calibration baths summary specifications

| Model | Range | Stability | Uniformity | Tank opening (diagonal) | Depth |

| Compact baths | ± 0.005 °C to ± 0.015 °C | ± 0.005 °C to ± 0.020 °C | 143 to 196 mm | 178 to 234 mm | |

| 6330 | 35 °C to 300 °C | ± 0.005 °C at 100 °C (oil 5012) ± 0.010 °C at 200 °C (oil 5017) ± 0.015 °C at 300 °C (oil 5017) | ± 0.007 °C at 100 °C (oil 5012) ± 0.015 °C at 200 °C (oil 5017) ± 0.020 °C at 300 °C (oil 5017) | 196 mm | 234 mm |

| 7320 | –20 °C to 150 °C | ± 0.005 °C at –20 °C (ethanol) ± 0.005 °C at 25 °C (water) ± 0.007 °C at 150 °C (oil 5012) | ±0.005 °C at –20 °C (ethanol) ±0.005 °C at 25 °C (water) ±0.010 °C at 150 °C (oil 5012) | 196 mm | 234 mm |

| 7340 | –40 °C to 150 °C | ± 0.005 °C at –40 °C (ethanol) ± 0.005 °C at 25 °C (water) ± 0.007 °C at 150 °C (oil 5012) | ±0.006 °C at –40 °C (ethanol) ±0.005 °C at 25 °C (water) ±0.010 °C at 150 °C (oil 5012) | 196 mm | 234 mm |

| 7380 | –80 °C to 100 °C | ± 0.006 °C at –80 °C (ethanol) ± 0.010 °C at 0 °C (ethanol) ± 0.010 °C at 100 °C (oil 5012) | ±0.008 °C at –80 °C (ethanol) ±0.012 °C at 0 °C (ethanol) ±0.012 °C at 100 °C (oil 5012) | 143 mm | 178 mm |

| Deep-well compact baths | ± 0.005 °C to ± 0.015 °C | ± 0.007 °C to ± 0.025 °C | 210 mm | 457 mm | |

| 6331 | 35 °C to 300 °C | ±0.007 °C at 100 °C (oil 5012) ±0.010 °C at 200 °C (oil 5017) ±0.015 °C at 300 °C (oil 5017) | ±0.007 °C at 100 °C (oil 5012) ±0.017 °C at 200 °C (oil 5017) ±0.025 °C at 300 °C (oil 5017) | 210 mm | 457 mm |

| 7321 | –20 °C to 150 °C | ±0.005 °C at –20 °C (ethanol) ±0.005 °C at 25 °C (water) ±0.007 °C at 150 °C (oil 5012) | ±0.007 °C at –20 °C (ethanol) ±0.007 °C at 25 °C (water) ±0.010 °C at 150 °C (oil 5012) | 210 mm | 457 mm |

| 7341 | –45 °C to 150 °C | ±0.005 °C at –45 °C (ethanol) ±0.005 °C at 25 °C (water) ±0.007 °C at 150 °C (oil 5012) | ±0.007 °C at –45 °C (ethanol) ±0.007 °C at 25 °C (water) ±0.010 °C at 150 °C (oil 5012) | 210 mm | 457 mm |

| 7381 | –80 °C to 110 °C | ±0.006 °C at –80 °C (ethanol) ±0.005 °C at 0 °C (ethanol) ±0.005 °C at 100 °C (oil 5012) | ±0.007 °C at –80 °C (ethanol) ±0.007 °C at 0 °C (ethanol) ±0.007 °C at 100 °C (oil 5012) | 210 mm | 457 mm |

| Standard baths | ± 0.0007 °C to ± 0.008 °C | ± 0.002 °C to ± 0.020 °C | 284 to 373 mm | 305 to 337 mm | |

| 7080 | –80 °C to 110 °C | ±0.0025 °C at −80 °C (methanol) ±0.0015 °C at 0 °C (methanol) ±0.0015 °C at 25 °C (water) ±0.003 °C at 100 °C (oil 5012) | ±0.007 °C at −80 °C (methanol) ±0.005 °C at 0 °C (methanol) ±0.003 °C at 25 °C (water) ±0.005 °C at 100 °C (oil 5012) | 284 mm | 305 mm |

| 7008 | –5 °C to 110 °C | ±0.0007 °C at 25 °C (water) ±0.001 °C at 25 °C (mineral oil) | ±0.003 °C at 25 °C (water) ±0.004 °C at 25 °C (mineral oil) | 373 mm | 331 mm |

| 7011 | –10 °C to 110 °C | ±0.0008 °C at 0 °C (ethanol) ±0.0008 °C at 25 °C (water) ±0.003 °C at 100 °C (oil 5012) | ±0.003 °C at 0 °C (ethanol) ±0.002 °C at 25 °C (water) ±0.004 °C at 100 °C (oil 5012) | 284 mm | 305 mm |

| 7040 | –40 °C to 110 °C | ±0.002 °C at –40 °C (ethanol) ±0.0015 °C at 25 °C (water) ±0.003 °C at 100 °C (oil 5012)" | ±0.004 °C at –40 °C (ethanol) ±0.002 °C at 25 °C (water) ±0.004 °C at 100 °C (oil 5012) | 284 mm | 305 mm |

| 6024 | 40 °C to 300 °C | ±0.001 °C at 40 °C (water) ±0.003 °C at 100 °C (oil 5012) ±0.005 °C at 300 °C (oil 5017) | ±0.002 °C at 40 °C (water) ±0.004 °C at 100 °C (oil 5012) ±0.012 °C at 300 °C (oil 5017) | 373 mm | 337 mm |

| 6050H | 180 °C to 550 °C | ±0.002 °C at 200 °C (salt) ±0.004 °C at 300 °C (salt) ±0.008 °C at 550 °C (salt) | ±0.005 °C at 200 °C (salt) ±0.020 °C at 550 °C (salt) | 284 mm | 305 mm |

Questions to ask in selecting a temperature calibration bath

- What is the temperature range of the bath?

- What are the recommended bath fluids and their operating ranges?

- What’s the bath stability and uniformity at temperature points in the range that interests you?

- What bath fluids were used to measure the stability and uniformity specs?

- Is the bath tank size adequate for the number and size of probes and sensors to be calibrated in a batch?

Please refer to the temperature calibration bath product pages referenced in the above table for complete product specifications. Contact a Fluke Calibration representative or visit www.us.flukecal.com/about/contact for more assistance in selecting the right temperature calibration bath and bath fluid for your application.

Keep learning

Why a Fluke calibration bath? - app note

Dry-Block Calibrators vs. Temperature Baths: Choosing the Right One for You - app note

Recommended products

Calibration reference probes & sensors

Get help

Need help choosing a product? Speak with a calibration equipment expert

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- About Us